PORTABLE 3D SCANNING

MOBILE SERVICE

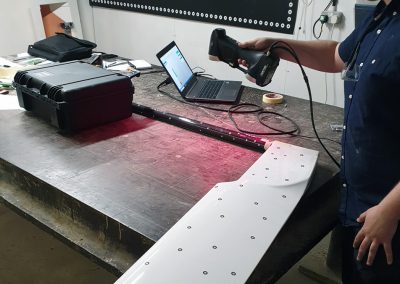

The system can be brought to virtually and environment to scan parts in situ / on site

STANDALONE SERVICE

Can be used to capture data for future use without commitment to any of our other services

PACKAGES AVAILABLE FOR EVERY BUDGET

Contact us for a further discussion about your needs

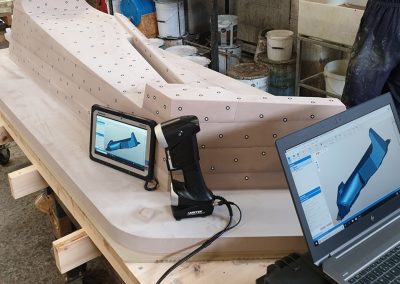

INNOVATION IN SCANNING

With the ever-increasing use of technology to achieve accuracy in manufacturing, MTAG invested in metrology grade portable 3D scanning equipment for use across the entire life cycle of parts manufacturing. The scanning technology itself allows data to be collected at a rate of 205,000 measurements per second to an accuracy of 0.04mm which gives an outstanding capacity to analyse large and small parts on and off-site with incredible detail. This is used to verify patterns prior to mould making, moulds prior to first part production, jigs prior to mass manufacture and as a part of regular quality assurance measures to ensure parts made are exactly as expected.

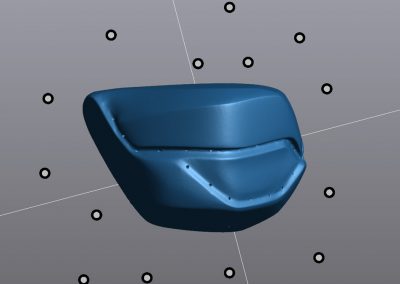

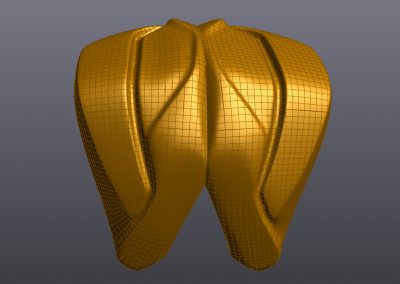

The associated software provides MTAG with the ability to identify errors, failures or anomalies which could impact on the strength, durability or aesthetics of a product prior to delivery to the customer. The capability to reverse engineer from OEM parts or produce data to manufacture moulds of obsolete/specialist parts in addition to examining and proposing upgrades to increase performance closes the loop on composites manufacturing systems keeping all development within a close team of staff.

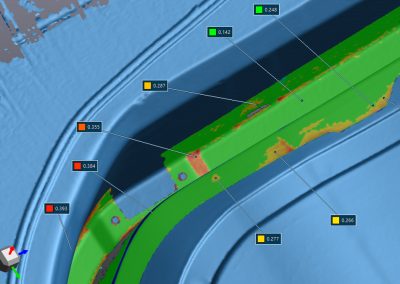

The technology replaces other more labour-intensive methods of quality control, with the scanner and software able to produce bespoke inspection reports by comparing parts to CAD data. Heat maps of the comparisons give a clear indication of conformance whilst illustrating the tiniest detail which could impact on the performance of parts.

This is available as a stand-alone service anywhere in the UK, please contact us here for help with your scanning needs.

APPLICATIONS

Pattern and Mould verification

PROJECTS

ACRO Aircraft Seating Thirty-six VARTM water heated Vinyl-Esther moulds

MRSS Combination of thirty-one handlay, VARTM and RTM Light moulds for a cab desk

RS Aero Suite of 4m Silicone bagged moulds

Radical Sportscars Carbon prepreg tooling for autoclave manufacture of race car wing

RS Sailing Machined aluminium tiller and centreboard closed moulds

Perudo Realisations Large Handlay mould for catering kiosks

Orbit Float 6 x Handlay moulds to be bonded to form a flotation pod

Sitech Handlay press mould to form arc-shields for London Underground